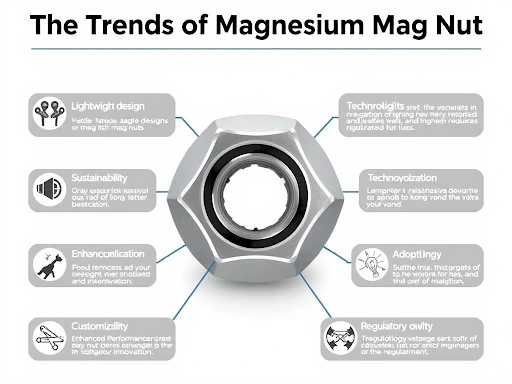

The Trends of Magnesium Mag Nuts

Found in many nuts, magnesium has long been known as an energy booster and bone health enhancer; muscle contraction/function; cardiovascular, gastrointestinal, and immunological function enhancer.

Mostly seen on wheels with wheel spacers, mag type lug nuts differ from other varieties (hex) by having a flat washer seat that lets them be fitted and withdrawn with more ease. Successful installation or removal of them calls for specific tools.

Future Developments in Fastening Techniques

Fastener makers are changing with creative design and production innovations that provide more accuracy and efficiency as manufacturing sectors move toward Industry 4.0 goals, hence improving worker safety. These developments increase safety both during manufacture and product distribution as well as offer more accuracy and efficiency.

These advances are driving a constant demand for flexible fastening solutions. Fasteners must be able to meet high quality and safety criteria while nevertheless performing consistently across a range of environments. This will lead to novel materials able to adapt to various conditions and more flexible manufacturing techniques produced.

For some orders, MEIGESI has already begun using cutting-edge technologies such 3D printing and automation into its manufacturing processes, therefore accelerating innovation and production times. By effectively applying these production techniques, MEIGESI has drastically shortened lead times and concurrently raised product flexibility and efficiency. Already using these technologies to hasten production time and creativity, MEIGESI

Another trend is the growing demand for professional fastener users to get more specialized education and training, which results in the development of online learning platforms and virtual training tools accessible remotely that provide further insight on fastening technologies’ principles as well as their application across a range of applications.

Mag Nuts: Their Function

Though they seem small, nuts are highly important for mechanics and engineering. Together with bolts, nuts provide stability and provide safety by tightly fastening tools or machinery.

Modern aluminum wheels increasingly have mag type lug nuts or tuned versions. Unlike conventional designs, these unusual lug nuts have a flat washer seat that rests flush on the wheel flange, call for specific tools to install and remove, and have longer threads to boost torque capacity.

Among other benefits, nylon nuts have greater acid and alkali resistance and do not create signal interference from eddy currents than metal equivalents. And nylon nuts weigh noticeably less!

Using Mag Nut Applications

Unlike their cousins with spherical or conical seats, which let them sit flush against wheels without exposing extra metal, mag type lug nuts have a flat washer seat. Aluminum wheels or older steel wheel applications where there isn’t enough of an accessible thread length for an Acorn style lug nut to be placed effectively can have this type of lug nut.

Still another type of lug nut are serrated flange lock nuts (SFLNs). These locks need an extra step during installation which could prove expensive, although their serrations on their mating surface help to distribute load more evenly over a larger area and prevent loosening and damage to delicate surfaces.

Still another choice are tuned type lug nuts. Unlike their counterparts, tuning lug nuts call for specific tools for installation and removal, therefore preventing theft. Additionally included are conical seating sections with 60 degree tapered threads to reduce stripping or loosening problems.

Mag Nu Manufacturing

Manufacturing weld nuts calls for advanced fabrication methods, sophisticated inspection tools, and strict quality control procedures. Apart from making sure their mechanical characteristics and dimensional precision are ideal for industrial use, quality assurance processes also support their safety for application in these fasteners.

Widely used for the production of welding nuts, stamping is a quick and accurate metal forming technique that greatly reduces manufacturing time and labor costs and provides excellent performance. Stamping dies provide consistent weld nut creation with homogeneous shapes and sizes due to their accuracy and durability; also, the flanging process provides resistance against tension forces and fatigue so boosting functionality and performance.

Making weld nuts requires a necessary stage of heat treatment. To enhance mechanical qualities and raise performance, this procedure heats the nut to particular temperatures then cools it at the right rate. Common heat techniques are tempering, quenching, and annealing.

After quality control and inspection, weld nuts are packaged according to customer requirements and delivered for usage in industrial settings. Built of low carbon steel or austenitic stainless steel (very corrosion-resistant and fit for many hostile conditions).

Read also: Types of Assortment Mag Nuts